The electric vehicle (EV) market is big news in the automotive landscape. Not only are new electric vehicles being purchased in record numbers by drivers in China, Japan, Europe, and North America, but the popularity of EVs is also fuelling a lucrative used electric vehicle market, too. In 2023, around 20% of all vehicles sold worldwide were electric or hybrid, a market share that is expected to exceed 50% by 2035.

Why Used EV Transport Is So Complex

Unfortunately for finished vehicle logistics businesses, electric vehicles come with more transportation complexities than their fossil fuel powered cousins. Most of these issues come from the hazards associated with shipping the lithium-ion batteries used to fuel these vehicles. As recently as June 2025, the roll on roll off (Ro-Ro) cargo ship Morning Midas was disabled and sunk in the Pacific following an on-board fire while in transit between China and Mexico. The ship was carrying approximately 3,000 cars, including 70 electric and 681 hybrid vehicles, and the fire originated on the deck where the EVs were stored. The most likely cause of this fire, as with many others in recent years (e.g. the Felicity Ace, Freemantle Highway, Pearl of Scandinavia etc), is thermal runaway in one of the stored lithium-ion batteries.

Transporting used EVs therefore comes with distinct challenges compared to traditional vehicles. Not only do EVs differ mechanically, but their value and safety are closely linked to their batteries, requiring extremely careful handling throughout the journey. The risks associated with electric vehicle transport are difficult to address on Ro-Ro ferries, where the battery must be in situ for the car to be driven on and off the ferry. This contributes to widespread delays, capacity issues, rising costs, and unpredictable delivery times on many shipping routes. These are just some of the most common issues when transporting cars, especially as volumes and demand surge.

How Trans-Rak’s Racking Systems Address These Challenges

Our finished vehicle racking systems provide a direct answer to the hurdles faced by electric vehicle logistics, especially for businesses considering car container shipping as an alternative to Ro-Ro. By optimising the way that your vehicles and their batteries are packed and secure within a car shipping container, our systems help streamline operations and deliver several tangible benefits. These include:

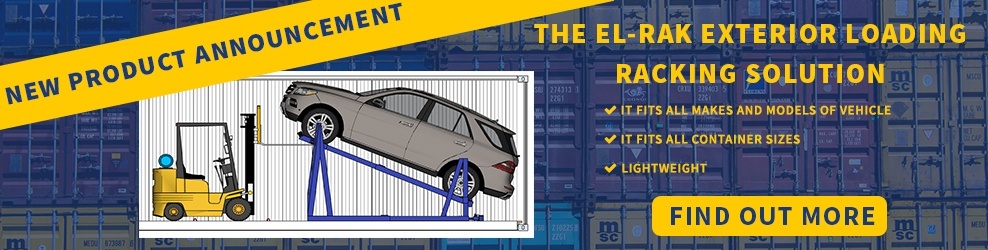

Space utilisation: Our R-RAK and EL-RAK systems can safely load multiple electric vehicles – often four more – into a single 40 foot container. The R-RAK lifts and tilts the vehicle to maximise container space, while the EL-RAK enables wider or varied vehicle models to be loaded externally and then moved into place efficiently.

Improved safety: Each finished vehicle racking system is made from durable, certified steel and designed to minimise vehicle movement and prevent damage in transit. Secure lashing and the strategic placement of vehicles inside the container helps to protect sensitive battery components, lowering the risk of fires and accidental damage.

Reusability: Our systems are designed to be extensively reusable, with a working life of 7 to 10 years or more and hundreds of return journeys. After use, the racks can be collapsed for efficient return shipment, with up to 60 R-RAKs per shipping container for the return leg.

Operational efficiency: Fitting more electric vehicles in each shipment reduces the total number of containers required, increasing speed to market and reducing the unit cost of each vehicle. The long lifespan of each racking system also helps you avoid the recurring expense of single use wooden racks, maximising your return on investment from each trip.

What Next?

Get in touch with Trans-Rak today to discover how our adjustable racking solutions support a safer and more sustainable global supply chain for used electric vehicles.