Working out how many cars you can fit into a standard 40ft HC container is no longer a manual exercise thanks to new software developed by WMG at Warwick University in conjunction with vehicle racking experts Trans-Rak International.

Based on the make and model of the cars to be transported, the ‘Container Optimiser’ programme can calculate the optimum combination and positioning to maximise the capacity and could halve freight costs.

Based on the make and model of the cars to be transported, the ‘Container Optimiser’ programme can calculate the optimum combination and positioning to maximise the capacity and could halve freight costs.

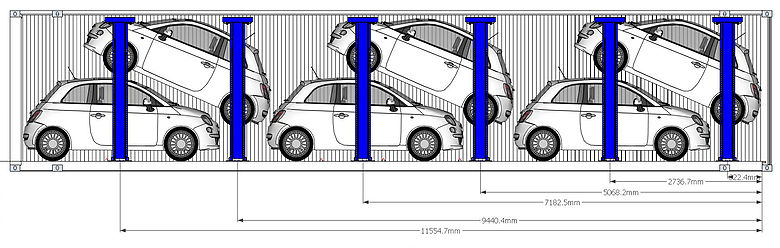

Researchers say the system, is a quick way to increase the number of cars that can be squeezed into one container from the current two to four.

“The solution has totally transformed the manual-based processes previously used for establishing the optimal placement of a set of cars,” said Piero Filippin, Innovation Manager at the University of Warwick.

The new software weighs up the various loading combinations which can be achieved with the highly flexible R-Rak vehicle racking system and produces a report on how to stuff each container, the exact position of the cars and even how best to load them.

By reducing the number of containers required to transport the cars via sea or rail, the software delivers further savings in terms of cutting carbon emissions with fewer journeys by road delivering the cars to their final destination.

Although the container optimisation software is not currently available to Trans-Rak customers, but is under development for 2017 as MD Paul Donaldson explains:

“The software “backbone” was designed in partnership with WMG. We are in discussion with other developers to improve and update the program to make it more efficient and have further capabilities.

“The aim is to have a software package for our customers to work out optimal loadings themselves in order to save them time and avoid the need for us to manually calculate each loading scenario."